Calkin’s 30-Year Milestone

“When I think about the biggest moments of my career at STC,” says Angie Calkin, “I would probably say the Nighthawk production line, our becoming ISO 9001 certified, and then my promotion to Vice President of Operations.”

Angie has seen many changes during her 30 years at STC, but these moments mark three significant shifts in her mind.

The Nighthawk production line fulfilled orders for transformers used in the Nighthawk brand of carbon monoxide detectors. At that point in the 1990s, the Nighthawk orders were the largest ever placed with STC.

“At that time, I was involved with Testing, Quality, and Electronics Production. Then I became Project Manager for the Nighthawk line—which shipped between 2,000 and 4,000 transformers per day. That is a lot compared to what we had been producing. We had three shifts running to meet the orders. We purchased new winding equipment. We hired new employees, so we were interviewing, hiring, and training. It was both very exciting and stressful.”

At the time, Angie felt she lacked the experience for the wide range of abilities the job required, but she learned quickly.

“You can imagine the complexity to ship that many parts each day, from having the material in place, to handling employee issues, to dealing with machine breakdowns, and then the logistics for shipping, Angie says with a laugh. “I can’t tell you how many times [husband] Jim and I made the 40-mile trip to the shipping center to drop off additional parts to be shipped.”

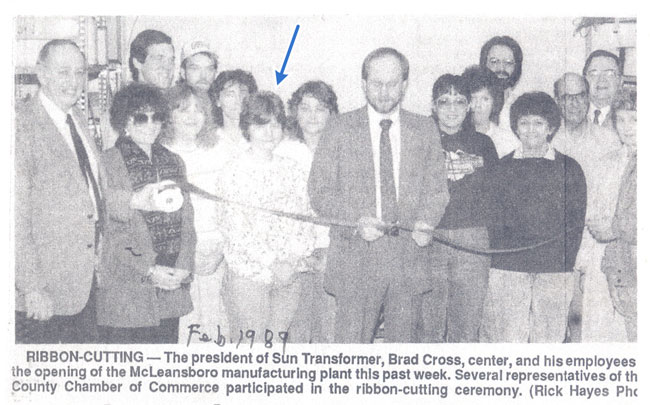

Angie started at STC as a production worker alternating between Electronics assembly and Magnetics (transformers). In 1989, STC moved across town to its current location. The move took a couple of months to complete, and Angie was the first one to relocate to the much larger facility. As a result, she worked alone for a month or two until the move was complete.

“Quality testing was an ongoing part of my responsibilities, but it got to the point there were projects we knew we couldn’t bid because we weren’t ISO certified,” Angie says. “We worked hard to become ISO 9001 certified. In addition to many other tasks, we wrote Procedure and Quality manuals, which we update as needed to maintain our ISO certification.”

After 18 years at STC, Angie was promoted to Vice President of Operations, and there was no question about the first priority to be addressed in her new position.

“I know when I took over, we were way behind on our production schedule, and it was a real challenge to catch up on,” says Angie. “It was at that point that I started communicating more frequently with customers—and you learn a lot of important things doing that. I started interacting with so many facets of our customer’s businesses, so you learn much more about what they require and why they require it.

Angie is pleased with the current state of STC.

“I think the company’s done well. I credit [STC President] Brad Cross for that, his leadership. The work we do now is a lot more high reliability, and it’s taken time to build up to that.”

When asked about Angie’s contributions to STC, Cross is quick to point out the benefits gained from her hard work and eye for detail.

“Angie’s high standards for order execution and quality impacts our entire organization.”

Thanks for your hard work and leadership during your time at STC Angie—and best wishes for the next 30 years!